Reduce Pulsation, Double Drive Output, and Improve Accuracy with Double-Y Tube Sets

Reduce Pulsation, Double Drive Output, and Improve Accuracy with Double-Y Tube Sets

Double-y tube sets rely on two “Y” connections assembled to a split-channel tubing configuration. Splitting the channels allows two channels of tubing to run through one pump – effectively doubling the flow. Double-y tube sets are typically used with either two stacked pump heads or a pump head specifically designed for double-y tube sets. As the pump operates, one channel “pulls” from the unification point upstream, while the other channel “pushes” to the unification point downstream – essentially “splitting” the fluid path. Splitting the fluid path provides not only twice the pump output (if the fluid path width is not reduced), but it can also greatly decrease downstream pulsation, while increasing dispensing accuracy. Additionally, adding an additional channel to a pump drive is very simple and does not require additional electric outlets.

Masterflex® double-Y tube sets

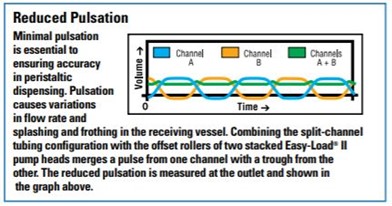

Masterflex double-Y tube sets can double flow rates while potentially reducing pulsation by up to 90 percent, resulting in increased flow accuracy. This can be achieved by offsetting the rotors in each channel and results in the green flow pattern in the diagram (shown on the right). One channel is pulling in fluid while the other is simultaneously pushing it out for a more even flow when the channels are united downstream. Reducing pulsation is ideal where foaming or pressure sensitivity (for example, in some fluid sensors) are a concern or for improved filling accuracy. Offsetting the rollers also effectively reduces the volume of fluid pockets observed downstream, which means greater resolution and repeatability in dispensed volumes and reduced potential waste from overage.

Alternatively, mechanical shear forces, from repeated occlusions, can be reduced by running the drive at the same volume output, but at a reduced RPM. With two pump channels, the output is doubled, so running at half speed produces the same flow as running one pump head normally. Reducing the RPM also reduces the overall shear acting upon the fluid. This is beneficial for live cells, large molecules, other biologics, some slurries, or other fluids carrying soft or hard particulates of various size (smaller than the tubing inner bore of course).

Options to consider when increasing channels with one drive

Masterflex offers a few ways to increase active pump channels with one drive. First, make sure the Masterflex drive can handle the torque required of two – or four – channels at once. This is easiest to determine by max speed on Masterflex L/S® drives. If the max speed is 100 rpm, it can handle up to four pump heads. If the drive runs up to 600 rpm, then it can handle two. Masterflex I/P® drives can handle up to two channels.

Stacked pump heads

Use Masterflex double-Y tubing assemblies with the offset rollers of two stacked Masterflex L/S Easy-Load®, Easy-Load II, or I/P Easy-Load pump heads to reduce pulsation and enhance accuracy in peristaltic dispensing. When these heads are stacked, the roller sets in adjacent heads are offset. While one roller is drawing fluid through one channel of the double-Y tubing the other is pushing it through the other channel. This results in an overall smoother flow (as described above) as the drawing action between fluid pockets in a peristaltic pump are compensated for downstream by the other fluid channel.

Masterflex UltraPharm™ pump head

Higher dosing and dispensing accuracy are key in many bioprocess applications and another option is the Masterflex UltraPharm pump head. Designed with offset rollers and planetary gearing with proprietary Masterflex L/S double-Y tube sets, the Masterflex UltraPharm pump head produces a gentle and low pulsation pumping action resulting in a highly accurate dosing and flow to ensure the greatest product integrity and uniformity. The Masterflex UltraPharm pump head is autoclavable and available in either aluminum or 316 stainless steel depending on application requirements.

Masterflex L/S Dual-Channel Easy-Load II pump heads

You can also use the Masterflex L/S Easy-Load II dual-channel pump head to double your output*, however the tubing is occluded using the same roller in both channels so pulsation will not be reduced as it would by using stacked pump heads or with the L/S UltraPharm pump head. To pump two synchronous channels, proper retention is necessary and requires the use of the same size tubing in each channel. These pump heads accept the four L/S Precision tubing sizes L/S 13, L/S 14, L/S 16, and L/S 25. You can achieve flow rates of 0.06 to 1000 mL/min—flow rate depends on drive rpm and tubing size. *Does not accept all L/S tubing sizes.

Most convenient option for double-Y tube sets

The most convenient way to get double-Y tube sets is to purchase Masterflex double-Y tubing assemblies. These are ready to use straight from the package and will eliminate the time and expense of making tube sets in house. Presterilized tubing is also available if that is a requirement.

Each formulation exceeds FDA and USP Class VI requirements and meets USP Class V (extractables) standards. The tubing is manufactured to pharmaceutical cGMPs and is autoclavable. A variety of tubing length and sizes are available.

For more information on double-Y tubing, see our full product range.